In the pursuit of pristine sound quality or undisturbed peace within our homes, the concept of room in a room soundproofing emerges as a revolutionary solution. This innovative approach not only enhances the acoustic environment of a space but also serves as a sanctuary from external noise pollution. Whether you’re a professional musician requiring a pristine recording environment, a remote worker in need of a quiet office, or simply seeking tranquility in a noisy neighborhood, this guide will walk you through the essentials of constructing a soundproof room in a room. Embrace the silence and discover the transformative impact of effective sound isolation on your work, leisure, and overall well-being.

Table of Contents

Materials Needed

Constructing a room in a room soundproofing setup requires a careful selection of materials to ensure effective noise isolation. Here’s a comprehensive list of materials you’ll need to embark on this DIY project:

- Framing Materials: Start with sturdy framing materials such as wooden studs or metal frames to create the structural skeleton of your inner room.

- Sound Insulation: Rockwool or fiberglass insulation is essential for filling the gaps between the structural framework, providing excellent sound absorption.

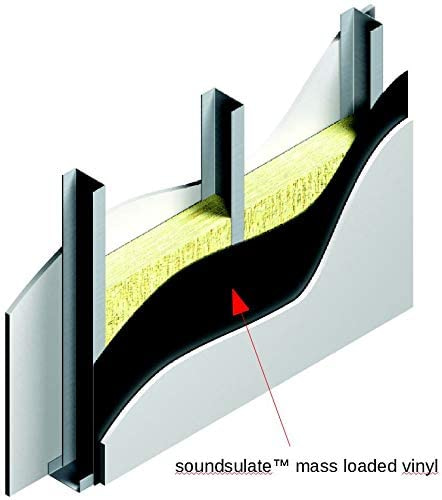

- Mass-Loaded Vinyl (MLV): This dense material acts as a sound barrier layer, significantly reducing the transmission of airborne noise.

- Acoustic Sealant: Use a non-hardening acoustic sealant to fill in gaps and seams, ensuring an airtight space.

- Drywall: For the walls and ceiling, use double layers of drywall with acoustic compound (Green Glue) between them for added mass and damping.

- Resilient Channels: These metal channels help decouple the drywall from the structure, reducing sound transmission.

- Acoustic Panels: For the interior, consider adding acoustic panels for absorbing echoes and further improving sound quality within the room.

- Door and Window Treatments: Install soundproof doors and windows, or use weatherstripping and door sweeps to seal existing ones effectively.

- Floor Underlayment: A dense, sound-absorbing underlayment beneath your flooring can reduce impact noise.

- Tools and Accessories: Don’t forget the necessary tools and accessories for installation, including saws, drills, screws, tape measure, and potentially a level.

Gathering these materials in advance will prepare you for a successful soundproofing project, creating a serene and acoustically isolated space within your home or workspace.

Now that we’ve covered the materials needed for your room in a room soundproofing project, the next logical step in our guide would be to delve into “Planning Your Space.” This section will provide essential guidance on measuring and designing the layout of your inner room for maximum sound isolation, including considerations for ventilation, electrical wiring, and optimizing the use of available space for acoustic benefits.

Given the detailed nature of this step, it will involve aspects such as:

- Determining the Purpose of Your Space: Tailoring your design to fit the specific needs, whether it be for recording, practicing musical instruments, or creating a quiet work environment.

- Space Measurements: How to accurately measure your existing space to plan the dimensions of your inner room effectively.

- Acoustic Considerations: Understanding how sound behaves in a room and planning your space accordingly to minimize sound leakage and maximize sound quality.

This preparation stage is crucial for a successful soundproofing project, ensuring that the construction phase proceeds smoothly and results in the desired level of sound isolation.

Planning Your Space For a Room in a Room Soundproofing

Embarking on a room in a room soundproofing project starts with meticulous space planning. This initial phase is critical to ensure the success and effectiveness of your soundproofing efforts. Here’s how to plan your space effectively:

- Assess Your Existing Space: Measure the dimensions of the room where you’ll be constructing your soundproof room in a room. Understanding the available space helps in deciding the size of the inner room and identifying potential challenges.

- Determine the Purpose: Define what the room will be used for — whether it’s a home studio, office, or a quiet retreat. The room’s purpose will influence the design and the soundproofing materials you’ll need.

- Consider Ventilation and Lighting: Plan for adequate ventilation and lighting within the inner room. A well-ventilated space is crucial for comfort, especially if you’ll be spending extended periods inside. Natural light sources or well-planned artificial lighting can make the space more inviting and functional.

- Sketch a Layout: Create a rough sketch of your planned room in a room, including the placement of doors, windows, and any specific acoustic treatment areas. This visual guide will serve as a blueprint for the construction phase.

- Select a Construction Method: Decide whether you’ll be using pre-fabricated soundproofing panels or building from scratch with timber or metal framing. Each method has its advantages and should be chosen based on your budget, available tools, and construction skills.

- Budgeting: Set a realistic budget for your project, considering the costs of materials, any necessary tools, and unforeseen expenses. Proper budgeting ensures that you can complete your project without compromising on quality.

By thoroughly planning your space, you set a solid foundation for the successful construction of your soundproof room in a room. This preparatory step ensures that you can move forward confidently, with a clear vision of the outcome.

Building the Framework

Constructing a room within a room begins with building a robust framework, a crucial step that lays the foundation for effective soundproofing. Here’s a concise guide on how to build this framework:

- Creating a Plan: Before any construction begins, draft a detailed plan of the framework. This includes the dimensions of the inner room, the location of doors, and any additional structural elements needed for soundproofing.

- Choosing Materials: Opt for materials that offer structural integrity and are compatible with soundproofing. Wooden studs are commonly used due to their ease of handling and effective sound-dampening characteristics when combined with soundproofing materials.

- Frame Construction: Erect the frame within the existing room, ensuring there’s enough space between the new frame and the existing walls to add sound insulation. The frame should be sturdy, level, and square.

- Using Screws Over Nails: For assembling the frame, use screws instead of nails. Screws provide a stronger hold, reducing the likelihood of any part of the structure loosening over time, which could compromise soundproofing.

- Decoupling: Consider implementing decoupling techniques to the frame to further enhance soundproofing efficiency. This can involve using special clips or constructing a double frame to physically separate the inner room from the existing structure, minimizing sound transmission.

- Doorway Planning: Incorporate a plan for a soundproof door within the framework. The door is a critical component and should be placed strategically to maximize soundproofing while ensuring functional access to the room.

This guide outlines the initial steps in constructing a sound-isolated room within another room, emphasizing the importance of a solid and well-thought-out framework as the foundation for effective soundproofing.

Insulation and Soundproofing Materials

After constructing the framework for your room in a room project, the next crucial step is selecting and installing the appropriate insulation and soundproofing materials. These materials are key to achieving the desired level of sound isolation and acoustic quality within your space. Here’s what you need to know:

- Rockwool or Fiberglass Insulation: These materials are excellent for filling the cavities within your walls and ceiling, providing both thermal insulation and sound absorption.

- Mass-Loaded Vinyl (MLV): A heavy, yet flexible material that acts as a sound barrier. Install MLV on walls, ceilings, and even floors to block airborne noise effectively.

- Acoustic Sealant: Use this non-hardening sealant to fill any gaps and seams in your construction. It’s crucial for creating an airtight space that prevents sound leakage.

- Drywall: Double-layering drywall with a damping compound like Green Glue in between is an effective strategy for adding mass and reducing sound transmission.

- Resilient Channels: Installing these metal channels between the drywall and the framing decouples the wall, which helps in reducing sound transmission.

- Acoustic Panels: For additional sound absorption, especially in high-frequency ranges, install acoustic panels on the walls and ceiling of the inner room.

- Door and Window Solutions: Soundproofing doors and windows or using seals and weatherstripping can significantly reduce sound leakage in these vulnerable areas.

- Floor Underlayment: A dense, sound-absorbing underlayment is essential for reducing impact noise. This is particularly important if the room will be used for music or any activity that involves movement or vibration.

Collectively, these materials work to dampen, absorb, and block sound, creating a serene environment that’s isolated from external noise. The effectiveness of your soundproofing will largely depend on the quality of materials used and the precision in their installation.

Installing Drywall and Acoustic Treatments

Once you’ve selected and installed the appropriate insulation and soundproofing materials for your room in a room concept, the next steps are installing drywall and applying acoustic treatments. These steps are crucial for enhancing the soundproofing efficiency and acoustic quality of your space. Here’s a guide to help you through the process:

- Installing Drywall: For added sound isolation, consider installing double layers of drywall with a damping compound like Green Glue in between. This compound reduces sound transmission by converting sound energy into a small amount of heat. Ensure that the drywall sheets are securely fastened to the framework, and use acoustic sealant to fill any gaps or seams.

- Decoupling Drywall: To further improve sound isolation, you can decouple the drywall from the framework. This involves using resilient channels or sound clips and hat channels, which create a mechanical separation between the drywall and the studs. This separation reduces the transmission of sound vibrations through the structure.

- Acoustic Panels: After the drywall is up, you can enhance the room’s acoustic quality by installing acoustic panels. These panels absorb sound waves, reducing reverberation and echo, and are particularly useful in spaces used for recording or practicing music.

- Sealing Gaps: Even the smallest gaps can significantly undermine your soundproofing efforts. Use acoustic caulk to seal gaps around outlets, light fixtures, and where the walls meet the ceiling and floor. This ensures that your space is as airtight as possible, preventing sound leaks.

- Soundproofing Doors and Windows: If your room in a room concept includes doors and windows, make sure they are properly soundproofed. This may involve installing special soundproof doors and windows or adding seals and weatherstripping to existing ones to minimize sound leakage.

- Final Touches: After installing the drywall and acoustic treatments, you can add decorative elements that also serve a functional purpose. For example, thick curtains can further dampen sound, and strategically placed rugs or carpets on the floor can reduce echo.

National Consumer Center offers you a chance to get a $500 gift card to Amazon. The payouts are quick, and you can use the Gift Card to pay for some of your Amazon products.

By following these steps, you’ll significantly improve the sound isolation and acoustic quality of your room in a room soundproofing project, creating a peaceful and quiet space suited to your needs.

Finishing Touches and Customization

After the structural elements of your room in a room soundproofing project are complete, including the framework, insulation, drywall installation, and acoustic treatments, it’s time to focus on the finishing touches and customization. These final steps are crucial for ensuring your space not only meets your soundproofing requirements but also suits your aesthetic preferences and functional needs. Here’s what to consider:

- Paint and Decor: Choose a paint color that reflects your style and apply it to the drywall. Consider using acoustic-friendly paint that contributes to sound absorption. Decorate the space to reflect its intended use, whether for music, work, or relaxation.

- Lighting: Install lighting fixtures that complement the room’s purpose. Soft, adjustable lighting works well for studios and home theaters, while bright, direct lights are suitable for workspaces.

- Acoustic Furniture: If the room will be used for recording or practice, consider adding furniture that doubles as sound absorbers, such as plush sofas, thick rugs, and heavy curtains.

- Customizing Acoustic Panels: Beyond their functional purpose, acoustic panels can be customized to add a visual element to your space. Many companies offer panels with printed designs or the ability to create a custom print.

- Tech Setup: Install any necessary technology, such as recording equipment, monitors, or a home theater system. Ensure cables are neatly managed and that any tech additions don’t compromise the soundproofing integrity.

- Ventilation: Don’t forget to address air circulation. A soundproofed room can become stuffy, so consider installing a silent ventilation system or air purifiers to maintain a comfortable environment.

- Final Inspection: Conduct a final walk-through of your space to ensure all elements are correctly installed and that the room meets your soundproofing expectations. Make adjustments as necessary to seal gaps or add additional sound-absorbing materials.

Sound sealing or weatherproofing for an air-tight seal

Airgaps need to be treated to ensure complete coverage and manage sound seeping in through the frame. It would be best if you did this on both sides and at the top of the frame. Weatherstripping requires little effort but, done properly; it’s an effective sound management method.

Most products use a peel-and-stick function. Surface preparation is required as the glue needs a clean area to ensure adhesion. An alcohol wash is not always required but is recommended. Installation should be done on the inner part of the frame.

You can use two methods for this:

Acoustic gasket

This is a foam rubber composite material that is a hollow “D” shape. When compressed, the gasket seals off and prevents airflow. If the gap is wide enough, you may end up with an air pocket which is just as effective as a soundproofing method.

Peel off the protective strip to expose the sticky side of the tape and then stick the gasket to the frame on all the edges as required.

Closed-cell foam

Acoustic-treated foam is the most commonly used material for this. It is compressed between the inner door frame and the door itself, preventing sound from traveling through.

Again peel-and-stick methods are commonly utilized for the application, which makes it easy to install.

By incorporating these finishing touches and customization options, you can ensure your soundproof room in a room project is not only functional but also a comfortable and aesthetically pleasing space that meets all your needs.

Maximizing Soundproofing Efficiency

To ensure your room in a room soundproofing project reaches its highest potential in terms of sound isolation and acoustic performance, consider the following tips:

Seal All Gaps: Even the smallest gap or crack can significantly undermine your soundproofing efforts. Use acoustic sealants to fill any gaps around windows, doors, and where different materials meet.

- Layering: Incorporate multiple layers of soundproofing materials. The combination of mass-loaded vinyl (MLV), drywall, and acoustic panels can offer substantial noise reduction.

- Decoupling: Implement decoupling techniques to mechanically separate two sides of a wall, ceiling, or floor. This can be achieved through resilient channels, staggered stud construction, or double-wall systems.

- Mass Addition: The more mass a barrier has, the better it will block sound. Adding extra layers of drywall with sound-damping compounds like Green Glue can significantly improve sound attenuation.

- Absorption Within Cavities: Filling the cavities in walls, floors, and ceilings with dense insulation material, such as rockwool or fiberglass, can absorb sound waves and reduce transmission.

- Floating Floors: For the highest level of sound isolation, consider installing a floating floor. This technique uses a layer of sound-absorbing material under the floor to decouple it from the structure.

- Door and Window Treatment: Doors and windows are common weak points in soundproofing. Use solid core doors, soundproofing seals, and double-glazed windows to minimize sound leakage.

- Test and Adjust: After completing the soundproofing, test the effectiveness by playing sound at different frequencies and volumes. Identify any weak spots and apply additional treatments as necessary.

The AcousticCurtain™ from Residential Acoustics

The AcousticCurtain™ is a soundproof curtain that blocks outside noise, solving your noise problems at minimal expense and without disrupting the comforts of your home. Each AcousticCurtain™ is hand-crafted and customized to fit the dimensions of your window.

To deflect sound, the curtain uses a dense, flexible, sound-blocking core that averages between 10-15 pounds — although much smaller or larger curtains may vary.

Other benefits

- Light-blocking: the AcousticCurtain blocks more than 99% of outside light.

- Thermal properties: AcousticCurtain soundproofing has insulating properties, lowering your home’s heating and cooling costs.

- Decor: available in a wide variety of colors, the AcousticCurtain™ pairs well with any living space.

The AcousticCurtain blocks most outside noise, dramatically transforming your home’s atmosphere.

By meticulously applying these strategies, you can significantly enhance the sound isolation and acoustical quality of your room in a room project, creating a serene environment suited for various uses, from home studios to quiet workspaces.

Good luck and happy soundproofing!

2 comments

Comments are closed.